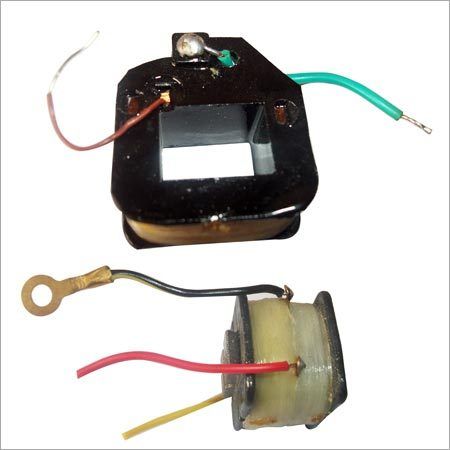

Automobile ST Coil

Price 49 INR/ Piece

Automobile ST Coil Specification

- Surface Treatment

- Galvanized

- Material

- Steel

- Technique

- Cold Rolled

- Coil Thickness

- 0.5 mm

- Coil Weight

- 120 kg

- Coil Length

- 150 m

- Hardness

- Medium

- Application

- Automobile Industry

Automobile ST Coil Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Carton Packaging

- Main Export Market(s)

- South America, Asia

- Main Domestic Market

- All India

- Certifications

- Yes

About Automobile ST Coil

We have marked a distinguished position in the allied domain by manufacturing and supplying an extensive gamut of Automobile S.T. Coils. Manufactured using quality tested raw materials in conformity with the set industry norms, the offered coils meet the set industry standards. These coils are specifically used to be installed in the vehicles. Also, these Automobile S.T. Coils can be purchased in various specifications at reasonable prices from us.

Features:

-

Excellent durability

- Durable finish

- Hassle-free operation

- Thermal resistance

Precision Engineering for Automotive Needs

Developed with a medium level of hardness and a uniform galvanized surface, our steel coils meet the strict requirements of the automotive sector. The cold rolling technique imparts both durability and consistent finish, making these coils ideal for automotive components requiring precise tolerance and strength.

Corrosion Resistance That Lasts

Galvanized coating on each ST Coil provides a protective layer, significantly extending its lifespan by preventing rust and oxidation. This makes the coils particularly well-suited for use in environments where protection against the elements is crucial, such as automotive manufacturing.

FAQs of Automobile ST Coil:

Q: How is the Automobile ST Coil manufactured?

A: The ST Coil is produced using high-quality steel that undergoes a cold rolling process to achieve a uniform thickness of 0.5 mm and medium hardness. After rolling, the coil is galvanized to enhance corrosion resistance, ensuring optimal performance in automotive applications.Q: What surface treatment does the ST Coil have and why is it important?

A: This steel coil is galvanized, which involves coating it with a layer of zinc. The galvanized finish protects the coil from rust and environmental damage, a critical benefit for automotive parts exposed to harsh conditions.Q: When should I consider using this coil for automobile manufacturing?

A: You should use this coil when precise thickness, moderate strength, and corrosion resistance are required for automotive components such as panels, frames, or chassis parts. Its characteristics make it suitable for a variety of structural and functional parts in vehicles.Q: Where is this ST Coil commonly applied in the automobile industry?

A: The coil is commonly used in the manufacturing of car body panels, structural supports, underbody components, and bracketsanywhere durability and a smooth, corrosion-resistant surface are essentials in automotive production.Q: What is the process for ordering this coil from your company?

A: As a manufacturer, supplier, and exporter based in India, you can place orders directly through our sales team or via our website. We ensure timely delivery and personalized service for both domestic and international clients.Q: How does the cold rolled technique benefit the coils performance?

A: Cold rolling refines the steels microstructure, increases dimensional accuracy, and imparts a smooth, even surface. This enhances both the mechanical properties and appearance, making it ideal for demanding automotive applications.Q: What are the main advantages of using this coil in the automobile industry?

A: The coil offers outstanding dimensional consistency, medium hardness for balanced strength and flexibility, superior corrosion resistance from galvanizing, and reliable performance thanks to strict manufacturing standards. This combination leads to longer-lasting automotive parts and improved production efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ST Coil Category

Auto ST Coil

Price 75 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Other, Mild Steel

Coil Weight : 500 kg to 2 Ton

Grade : ST37, ST52, ST44

Rear Brake Switches Coil

Price 75 INR / Piece

Minimum Order Quantity : 100 Pieces

Warranty : 6 MONTH

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS